circlebtechnologies

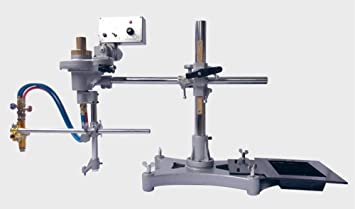

You may be required to manufacture circles and discs as a carpenter or a mechanical sculpture maker. Whether the circles are for a shop clock, turntable. For the circular tabletops or toy wheel, the primary aim is the same regardless of whether the circle is sliced. The circle should be precise and efficiently sliced. There are around a half-dozen distinct methods for cutting circles. This post will teach you how to cut a nice circle and use each technique to its full potential. If you’ve ever struggled with circular cutting, here are several tools. and alternatives to consider. You can also search for “circle cutters near me” to find a place for perfect circle cutting.

Cutting the Circle by Hole Saw

When drilling circles with a hole saw, use gentle pressure. They withdraw it frequently to avoid trapping sawdust. Using a hole saw and a backing board. and must be the most straightforward technique to manufacture little circles on the planet. Aside from the backer board, you might want to know two more drilling suggestions.

First, you might have realized that a hole saw’s cutting depth may be double. Begin drilling with the hole saw on one side of the workpiece. Then flip it over and continue cutting using the same pilot hole.

Second, starting with a sharp hole saw and not forcing The saw into the wood is the key to cutting a burn-free disc. Allow the teeth to cut gradually. Retract the hole often saw to prevent friction and aid in removing sawdust.

Cutting the Circle Using a Band Saw

The same approach applies to cutting circles using a jig on a band saw. The workpiece rotates on a pivot pin, cutting a circle by spinning the saw blade.

Start with a plywood base the size of the band saw table and a miter slot cleat attached to the bottom. If you need a quick, simple circular jig. Place the cleat in the miter slot and the jig in the spinning blade until. The back edge of the base is level with the table edge.

Below the jig, secure a block to halt it. Draw a line parallel to the blade and even with the teeth’ tips across the jig. A finish nail pivot should be inserted here.

Drill a tiny hole in the middle of the bottom of the workpiece and position it. The finish nail set in the jig to utilize it. The clamp the jig in place on the saw table by pushing it forward until it stops. First, spin the workpiece clockwise into a cross-grain to cut a circle. If necessary, use a side table to assist in supporting heavy workpieces.

Bottom Line

The Circle Cutter makes it simple to cut circles out of any creative material. And making it ideal for creating windows on handcrafted cards, scrapbook pages, and more. Therefore, if you want to make a table or a clock in a circular shape. You can find yourself a perfect cutting machine.

Conclusion

The highest quality circle cutter requires premium quality tools. A circle cutter serves the purpose effectively. The circle cutter is efficient, easy to use, and durable. This tool is best to get a clean and precise cut anytime and in any situation.